Results 721 to 750 of 1472

-

2014-07-31, 04:56 AM (ISO 8601)Barbarian in the Playground

- Join Date

- Feb 2010

- Location

- Slovakia

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

When we are talking about steel swords, main thing to remember is huge range of "steels" they were made of. Some of them aren't even steel by modern definition, but something called carburized iron. Carbon content ranges from .1 to about .8, way beyond modern carbon steel grades. See more here: http://www.myarmoury.com/feature_bladehardness.html

http://www.tameshigiri.ca/2014/01/21...ng-metallurgy/

As for bronze being bent by the bone, no, it's not even blunted that much, but it isn't able to stand up to steel. If you love swords, and are faint of heart, steer away from this link: https://www.youtube.com/watch?v=ngjMtzJ6xgQThat which does not kill you made a tactical error.

-

2014-07-31, 06:02 AM (ISO 8601)Ettin in the Playground

- Join Date

- Feb 2012

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

People may well be exaggerating on the difference between iron and bronze, but:

One quick thing, is that the steel blade can be longer, should you so desire. The long medieval swords would have been impossible without steel. Your players may want two-handed swords (in many systems this is a strictly superior weapon to other swords), in which case they will need steel.

But steel holds its edge longer, as you've noted, which is a huge advantage in large, protracted battles. Once the preliminary clashes are over, and supposing nobody has broken and run yet, things get down to 'who will break first'. It would be a big thing in morale (not to mention actual efficiency) if you feel like your weapon isn't biting very well any more. Or if you feel your enemy has an advantage in this, say fewer of their spear tips have broken, so they're still using their spear formation, while most guys on your side are down to their swords. Even later in the fight it gets worse. At Thermopylae, the Greek rearguard was said to have been reduced to fighting virtually unarmed (with fists and teeth) at the end. That may have been artistic license to some degree, but it shows how weapons degraded rather fast in battle. Compare to Cannae, a much longer battle, where the iron swords were said to have been blunted by the slaughter towards the end, but they were still being used.

There's also arrows to consider. The commander may be more hesitant to use up expensive bronze-tipped arrows than relatively cheaper iron-tipped ones. There may simply be more arrows to spend for the iron-users. Say that the bronze-users are out of arrows, but the iron-users still keep up a light peppering on enemies not actively engaged, stressing the other side even while they're gathering their mental and physical strength for another clash. Again a big thing in morale.

On a strategic level, having iron weapons would likely mean there were a lot more of them (because, as has been mentioned, iron is more plentiful and steel easier to make and work with than bronze). If the bronze-wielders each had a spear and a short sword, the iron-wielders may have a couple of javelins, a iron buckle on their shield, and then also spear and sword. On the armour it would be similar, there would be more helms, greaves, etc. for the same money/effort in iron.Last edited by hymer; 2014-07-31 at 06:05 AM.

My D&D 5th ed. Druid Handbook

-

2014-07-31, 06:21 AM (ISO 8601)Ogre in the Playground

- Join Date

- Aug 2013

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

That actually answered a question I was going to ask. What happens when the bronze meets steel.

So far it seems,

1) easier/cheaper to find raw-materials

2) steel meets bronze and steel wins, this alone would be kinda important as to why you'd switch to steel

What I'm curious about still is maintenance. Which metal is easier to repair, maintain and reshape, resharpen and so on.

I'm reminded when the Mythbusters tests "paper armour", which while performing equally to period metal armour, actually was lighter, fell down where each part (was a scale armour) was more or less one use only compared to the metal armour which a smith could just repair, vs remaking.

-

2014-07-31, 06:33 AM (ISO 8601)Ettin in the Playground

- Join Date

- Feb 2012

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

The main difference there is that to repair bronze, you could warm it up and hammer it back together by adding a little bronze to make up for what's lost, but you would have a much weaker blade than you had before. To get really good quality you melt the bronze down and recast it, a much more time- and fuel consuming process.

Steel is easier to repair, since it does quite well with heating and hammering. You don't generally (or at all?) cast steel blades anyway, so the repair can be as good as the original forging. Arrow points, perhaps, would be cast even as iron/steel, as they're generally single-use, I expect.

As for armour, I don't feel so confident. I think bronze would do better there (though still not as good as the ferrous solution), in that repairing it by heat-and-hammer would be less of a reduction in quality there, because it's thicker than the working part of the blade. Even so, you'd probably prefer to melt it down and recast it after the war, or at least before the next one, to make sure your stuff is top notch.

I don't really know how much effort goes into keeping bronze in working order compared to iron. Iron rusts, obviously, and so needs careful looking after. Bronze gets that greenish surface (which is unacceptable for blades i expect, but probably okay for armour), but then stops degrading at that.Last edited by hymer; 2014-07-31 at 06:36 AM.

My D&D 5th ed. Druid Handbook

-

2014-07-31, 06:49 AM (ISO 8601)Ettin in the Playground

- Join Date

- Jun 2006

- Location

- Poland

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Iron and steel items weren't really cast up to the widespread of blast furnace, and even then it was mainly used to cast a material, metal.

As far as I understand, bronzes generally actually resist metal fatigue better than most steels, so actually reshaping, bending and repairing them on serious scale might have been possible.Avatar by KwarkpuddingThe subtle tongue, the sophist guile, they fail when the broadswords sing;

Rush in and die, dogs—I was a man before I was a king.

Whoever makes shoddy beer, shall be thrown into manure - town law from Gdańsk, XIth century.

-

2014-07-31, 07:12 AM (ISO 8601)Ogre in the Playground

- Join Date

- Feb 2007

- Location

- Bristol, UK

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Wushu Open Reloaded

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Wushu Open Reloaded

Actual Play: The Shadow of the Sun (Acrozatarim's WFRP campaign) as Pawel Hals and Mass: the Effecting - Transcendence as Russell Ortiz.

Now running: Tyche's Favourites, a historical ACKS campaign set around Massalia 300BC.

In Sanity We Trust Productions - our podcasting site where you can hear our dulcet tones, updated almost every week.

-

2014-07-31, 10:21 AM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

The main functional difference between bronze and true tempered steel such as you would see in most medieval swords (as opposed to 'steely iron' and a lot of low-carbon or poorly heat treated steels that you find in earlier iron age swords) is that steel is quite flexible and springy. Bronze can be malleable but I've never seen a bronze weapon that was made springy in that way*. Copper alloys tend to bend or dent and stay that way until fixed - one of the most important characteristic of a good steel sword is that it is very springy and can bend and twist all over the place and return to form (which you can see if you watch super slow motion videos of sword cutting).

Bronze weapons remained popular long after iron became known and even after the advent of true steel. Bronze mace heads for example were still being used into the 17th Century. Armor too. The romans were still using Bronze or brass helmets well into the Imperial era.

I think the economic differences are the primary factor differentiating bronze from iron weapons, as well as weight to some extent (bronze is a little bit heavier by volume) in the early centuries of the Iron Age. But as others mentioned from pretty early on you did have Crucible steel weapons (wootz et al) as well as pattern welded weapons and these would be clearly superior. Still, when you are talking about relatively short single-handed swords, the differences may not be huge. With longer bladed swords are made in bronze they seemed to sometimes have riveted hilts which can't be very sturdy, so durability probably becomes a more important factor. And as hymer mentioned, you can't really have two-handed or hand-and-a-half swords until and unless you have pretty good steel.

Martin that was an interesting video with the Bronze sword, I'd like to see something similar with maybe better replicas (of both the steel and Bronze weapon) and performed by someone with more experience of cutting. I should note though, when you clash two sharp (or even more or less blunt) steel swords together, one or both of them will have a ding like that.

My medieval replica sharps could have cut all the way through all of those media that he was barely scratching very easily, you can see some youtube videos of people cutting through deer carcasses and so on. They also for example cut through tatami with dowels inside and cloth coverings (sometimes multiple times on the same tube in the same cut) routinely in HEMA cutting competitions these days, not to mention Japanese and Korean ones, but that is a combination of the quality (and type) of the sword with some significant experience in cutting. So I really don't know I that means my Albion Constable is vastly better as a sword because it's steel or not bronze or just because of the experience level of the cutter. Cutting takes some practice to learn.

G

*Apparently phosphor bronze can be made springy and was known in antiquity but I've yet to see evidence that it was used for weapons - it would be interesting if it was.

-

2014-07-31, 01:53 PM (ISO 8601)Titan in the Playground

- Join Date

- May 2007

- Location

- Tail of the Bellcurve

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

The riveted hilt thing is really only true I think of the very early Mycenaean Type A and to some extent B and C weapons. Apparently replicas are fairly sturdy when used properly, i.e. for draw cuts and thrusts instead of percussive blows, although they hold up surprisingly well to that also. Which, given the extremely pronounced central rib and very narrow blade of the Type As, is almost certainly not how they were meant to used anyway. The later bronze swords, with fully developed hilts, seem like if anything they'd be much less likely to break at the hilt than a typical sort of iron blade with a narrow tang. There's just a lot of metal in there, and it's very deliberately distributed. In some of the Type G swords the hilt has a well developed 'I' profile, with the crosspieces actually folded back over the haft material.

I don't think you'll probably get a much better replica than Neil's. I don't know of anybody else who does the hammer-forged edges like he does, or that casts into hot molds to get a properly thin blade. I don't think throwing a bronze sword up against modern high carbon steel is particularly informative though, since that wasn't exactly what was being produced circa 1200 BC, when iron was really getting going.Martin that was an interesting video with the Bronze sword, I'd like to see something similar with maybe better replicas (of both the steel and Bronze weapon) and performed by someone with more experience of cutting. I should note though, when you clash two sharp (or even more or less blunt) steel swords together, one or both of them will have a ding like that.Blood-red were his spurs i' the golden noon; wine-red was his velvet coat,

When they shot him down on the highway,

Down like a dog on the highway,And he lay in his blood on the highway, with the bunch of lace at his throat.

Alfred Noyes, The Highwayman, 1906.

-

2014-07-31, 02:50 PM (ISO 8601)Titan in the Playground

- Join Date

- Apr 2009

- Location

- Germany

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

That's an.... interesting thing to say.

I don't have any personal experience, so what I see one persom claim is as good as that of another, so you might still be right.

But I jst watched this video on the subject, which snowblizz seemed to not have spotted: https://www.youtube.com/watch?v=C4qLhq5V2-oWe are not standing on the shoulders of giants, but on very tall tower of other dwarves.

Spriggan's Den Heroic Fantasy Roleplaying

-

2014-07-31, 03:10 PM (ISO 8601)Bugbear in the Playground

- Join Date

- Sep 2010

- Location

- Albuquerque, New Mexico

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Have any tests of bronze swords managed to cleave bone as steel sword do? I'm sure some of the difference comes from the lower number bronze-sword tests, but none of the ones I know of demonstrated the ability to cut through bone. Even a single-handed steel sword, on the other hand, can in one blow cut 6+ inches into a human skull, fully sever the neck, remove an arm at the shoulder, cut off a leg, hack through a pike shaft, etc. Such feats require skill, strength, and sharp blade, but we have countless historical accounts.

Also, by the 14th century or so in Europe, swords with at least decent edges became fairly common. Even a solid minority of Roman swords tested had edges much harder than bronze.Last edited by Incanur; 2014-07-31 at 03:11 PM.

Out of doubt, out of dark to the day's rising

I came singing in the sun, sword unsheathing.

To hope's end I rode and to heart's breaking:

Now for wrath, now for ruin and a red nightfall!

-

2014-07-31, 03:53 PM (ISO 8601)Titan in the Playground

- Join Date

- May 2007

- Location

- Tail of the Bellcurve

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Really, what somebody needs to do is to fabricate the same sword in bronze, early iron age 'steel', and maybe a couple later steels as well, then compare them. Some of the later bronze age blades were also made in iron, I know of examples of both the Halstatt Mindelheim and the Naue II, so it would even be a rather authentic comparison.

Blood-red were his spurs i' the golden noon; wine-red was his velvet coat,

When they shot him down on the highway,

Down like a dog on the highway,And he lay in his blood on the highway, with the bunch of lace at his throat.

Alfred Noyes, The Highwayman, 1906.

-

2014-07-31, 04:41 PM (ISO 8601)Ettin in the Playground

- Join Date

- Feb 2012

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

The part that's relevant to this conversation starts about 5 minutes in. For reasons I don’t quite understand, the presenter compares a bent bronze sword with a steel sword that’s broken in half, and says that the bronze sword would be easier to repair. Well of course it would, one is bent and one is broken. The tendency of bronze to become bent is also higher than the tendency for a steel blade to do so (at least to bend and stay bent). So this comparison seems of dubious usefulness. I don’t know why he seems to imply you can’t recycle steel ‘back then’. I wonder how he thinks they got iron out of iron ore in the first place. While they're doing that, throw the old iron tools and weapons in with the ore, and voilá.

I think the presenter wants to ‘sell’ bronze as a cool material here, so he may be spinning the case somewhat. At least, that's my guess.Last edited by hymer; 2014-07-31 at 04:42 PM.

My D&D 5th ed. Druid Handbook

-

2014-07-31, 08:46 PM (ISO 8601)Ogre in the Playground

- Join Date

- Sep 2008

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

My understanding is that bronze is easier to work (lower temperatures and quite malleable), and very straightforward to recycle. I think it was even common to cast bronze swords, rather than forge them. So while the material itself was typically more expensive, the labor costs were probably lower. It was a very popular material for cannons for a long time.

-

2014-08-01, 03:35 AM (ISO 8601)Ogre in the Playground

- Join Date

- Feb 2007

- Location

- Bristol, UK

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Wushu Open Reloaded

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Wushu Open Reloaded

Actual Play: The Shadow of the Sun (Acrozatarim's WFRP campaign) as Pawel Hals and Mass: the Effecting - Transcendence as Russell Ortiz.

Now running: Tyche's Favourites, a historical ACKS campaign set around Massalia 300BC.

In Sanity We Trust Productions - our podcasting site where you can hear our dulcet tones, updated almost every week.

-

2014-08-01, 04:44 AM (ISO 8601)Ettin in the Playground

- Join Date

- Feb 2012

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

I've never had anything practical to do with bronze, so I will admit to no real experience there. And my first-hand experience with iron is limited to, as a boy, seeing the making of a knife from bog iron, and the occasional blow at a hot horse shoe or a nail since then. I'm not a licensed smith or anything. That said:

You cast bronze for weapons purposes, and for a sword you then work it with the hammer to press it and get the edge harder than it otherwise is with casting. This means you have to make a cast, and heat the bronze to melting point, pour it in, wait for it to cool, and then you get on with the hammering.

Iron melts at several hundred degrees higher than copper, so casting iron takes longer. As someone above pointed out, it hasn't been done regularly until industrialization hit. Since steel swords are not cast but forged, you should not compare casting one material to casting another, because you won't need to cast the steel. You can heat steel to the point where you can work it in a simple bonfire (I've done that). I expect you can work bronze at a lower temperature, but both are very easy to achieve even for a field repair.

I think the major maintenance on bronze is sharpening it. In ancient Rome, some people had slaves with the specific purpose of sharpening a man's bronze razors (and I guess shave him too). Being clean shaven was a way to show you could afford such extravagance. For bronze to really work as well as it can, it has to be honed a lot. The major maintenance on steel is keeping rust off it. I don't know which is more work; I guess it might well depend on how much use it sees. If it's stored between wars, bronze wins handily, as you only need to sharpen it before the first battle of the next war. On the other extreme, if you're in something like a guerilla or raiding campaign, you'd rather have the steel weapon, as it will be battle-ready even when your side gets surprised. You can work on keeping the rust out any time, and if you couldn't the hour before battle, no harm done to your fighting ability.

When it comes to repairing battle damage, I still hold the steel wins out. It takes a beating better, which means it is less likely to require maintenance in the first place. You can beat a new edge on it if it has taken bad damage. If the bronze has taken that kind of damage, the blade is in danger of breaking from the weakness, and it has to be melted down and made again from scratch. And the bronze weapon would be a lot more likely to take such damage.

Edit: Just looked up the bronze cannon. They were popular exactly because cast bronze bends easier than cast iron. A cast iron cannon is more durable, but it will likely show no signs when it's about to crack. A bronze cannon would visibly change when damaged by use. So you could stop using them, and so have less risk of the cannon blowing up. I'm sure the cannon crew appreciated that.

Last edited by hymer; 2014-08-01 at 06:40 AM.

My D&D 5th ed. Druid Handbook

-

2014-08-01, 05:33 AM (ISO 8601)Barbarian in the Playground

- Join Date

- Feb 2010

- Location

- Slovakia

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

One more video, just ignore the way he holds the shield when simulating one-on-one: https://www.youtube.com/watch?v=EJUIsTQ6eGs

Also, one more by Skallagrim (who doesn't have the best cutting technique - then and again, mine will probably be no better once the damn albion finally arrives...): https://www.youtube.com/watch?v=nVSb7vfra9g

As for HEMA test cuts, most of them I've seen are done with weapon length you don't get out of bronze. Even messer ones are usually with humungous messers. To get valid results, you would pretty much need to compare, say, bronze gladius to steel one - comparable blade geometries and all that. If someone actually does this, please send me a video.

As for maintenance, one thing you need to remember is that how easy it is isn't everything. While I can straighten out my bronze sword over my leg, I really don't have the time to do it in the middle of battle (tends to result in damage to my favorite organs), so from end user point of view, it's actually better to have something that can last longer and then be carted off to a smithy to properly fix.

Bronze armor, on the other hand, was phased out for a very simple reason - it's heavy, since bronze is heavier than steel (one of reasons why it was popular for maces). Also, you can't really make mail out of bronze, and why mail displaced plate in late roman period and early middle ages is an entirely different can of worms.That which does not kill you made a tactical error.

-

2014-08-01, 07:34 AM (ISO 8601)Ogre in the Playground

- Join Date

- Feb 2007

- Location

- Bristol, UK

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

It's about 10% heavier than the same volume of steel, that's really not reason enough to stop using it. It's also harder-wearing, since it doesn't rust like anything containing iron. Bronze armour went away because it was more expensive and the skills to work bronze into armour was dying out in favour of cheaper, more readily-available iron and coal/charcoal.

Largely because the lorica segmentata was rubbish. Unnecessarily complicated to make, harder to maintain, and not already around in large quantities, like the lorica hamata. It was a faddish piece of kit that was around for a short time then dropped. No doubt some crony of the emperor or someone close to them won the contract to make it, and merrily lined their pockets all the while. Note that centurions continued to wear mail (or scale) even while the poor legionaries were lumbered with "plate".Last edited by Kiero; 2014-08-01 at 07:37 AM.

Wushu Open Reloaded

Actual Play: The Shadow of the Sun (Acrozatarim's WFRP campaign) as Pawel Hals and Mass: the Effecting - Transcendence as Russell Ortiz.

Now running: Tyche's Favourites, a historical ACKS campaign set around Massalia 300BC.

In Sanity We Trust Productions - our podcasting site where you can hear our dulcet tones, updated almost every week.

-

2014-08-01, 09:54 AM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Bronze weapons were indeed cast, while all iron or steel blades were forged. Cast iron isn't suitable for use in weapons. Being able to cast spearheads, arrowheads, knives etc. means you can make a lot more of them faster, I think, and closer to identical in performance.

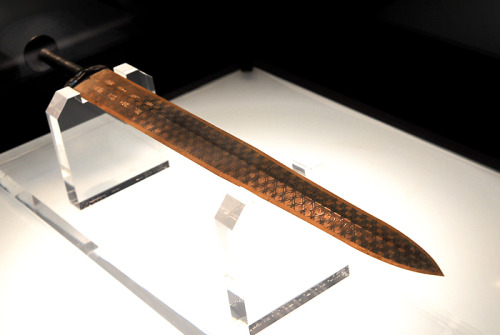

http://en.wikipedia.org/wiki/Sword_of_Goujian

Some bronze swords however, by the late Bronze Age, were often being made with different alloys almost in the same manner as pattern welding (there were many bronze and other copper alloys such as arsenic 'bronze' which had different degrees of malleability, hardness, weight, ductility etc.) in China for example they actually used alloys with different hardness for the edges and the core and so on. This is what I meant when I said a better sword (all due respect to that smith). In the last fifteen years of making higher end replica steel swords that people were actively cutting with, (and posting videos to youtube once that came out) and people going and measuring antiques with durometers and calipers every centimeter before we started having replicas which could cut or even just handle anywhere near as well as decent antiques. I suspect they could move the bar a little closer to what antique late Bronze Age swords were really like and get better performance.

Steel swords were also made in a similarly complex manner as the better bronze ones were both in the early Iron Age and later in the medieval period as Petter Johnnsson (speaking of higher end replicas - peter is the one who did a lot of that measuring I mentioned, for Albion) has shown, and were not simple homogenous metal.

Also, I don't agree on one thing, you can't forge a sword in a campfire. You need a bellows. With wind blowing across a fire you can get it amazingly hot in a short time, we've done this with a cheap hairdryer blowing through a pipe, but more importantly you can control the heat which is very important for forging and even more so for tempering. The temperature ranges you need for forging carbon steel are fairly tight, you get it too hot and you'll lose all the carbon, and the temperature that iron or steel become malleable isn't that far below where they melt. I've only played around with a forge a little bit, I'm not an expert, but I've seen what happens when you get it too hot (including total disintegration of a billet) and if it's not hot enough, you really can't do anything with it.

Someone said they required a lot of wood to make iron, this was true up until around the 13th Century, but by then they were using coal.

I think keeping steel from getting rusty is indeed very much one of the major downsides compared to bronze. You have to keep it oiled all the time which is a chore especially if you live in moist or humid area (and almost all medieval towns are on rivers, shorelines, lakes etc.). I learned about this when I got some real carbon steel swords for the first time and some carbon steel chef knives. It's much more of a pain in the arse! We generally aren't used to it because we are mostly exposed to chrome alloy stainless steel. This is why I only keep 2 or 3 'sharps' these days, plus my 2 feders, because it's a bit of work to keep up with.

GLast edited by Galloglaich; 2014-08-01 at 10:00 AM.

-

2014-08-01, 10:27 AM (ISO 8601)Bugbear in the Playground

- Join Date

- Sep 2013

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

It also takes significantly more complicated facilities to do so (and to anneal it to relieve any stresses in the blade), which could be another reason for bronze weapons and armour hanging around well into the iron age - the smiths that accompanied armies in the field may not have been able to transport suitable equipment and supplies to maintain iron weapons properly.

Or you cover the blade with something that will keep moisture off it before long-term storage - an oil-soaked cloth, for example.I think the major maintenance on bronze is sharpening it. In ancient Rome, some people had slaves with the specific purpose of sharpening a man's bronze razors (and I guess shave him too). Being clean shaven was a way to show you could afford such extravagance. For bronze to really work as well as it can, it has to be honed a lot. The major maintenance on steel is keeping rust off it. I don't know which is more work; I guess it might well depend on how much use it sees. If it's stored between wars, bronze wins handily, as you only need to sharpen it before the first battle of the next war.

-

2014-08-01, 11:18 AM (ISO 8601)Ettin in the Playground

- Join Date

- Jun 2006

- Location

- Poland

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

I guess it heavily depends on place and methods, but I don't think it would be true, generally.

Coal was generally only seriously used with large scale blast furnaces, and comparatively late too - Wikipedia claims 1709 - earlier blast furnaces were powered by charcoal.

First blast furnaces were apparently unpopular for long time as far as weapon production goes, anyway, because smelted iron had to be reforged for proper structure, and apparently, sulfur contamination occurring in coke blast furnaces was particularly detrimental.

Modern methods of course allow controlled proccesses as well as desulfurization when needed. , but in past times, it would be a problem.

I know that in Poland at least, any arms&armor production project since 16th century was universally attempted near some large forest area.

Don't think it would be different in other places, although countries like England would most obviously import wood and charcoal at this point.

Robin Hood : Prince of Thieve arrow casting scene was probably Hollywood's best take on this : so much wrong in humble ~3 seconds of tape.Also, I don't agree on one thing, you can't forge a sword in a campfire. You need a bellows.

Last edited by Spiryt; 2014-08-01 at 11:23 AM.

Avatar by KwarkpuddingThe subtle tongue, the sophist guile, they fail when the broadswords sing;

Rush in and die, dogs—I was a man before I was a king.

Whoever makes shoddy beer, shall be thrown into manure - town law from Gdańsk, XIth century.

-

2014-08-01, 12:16 PM (ISO 8601)Ettin in the Playground

- Join Date

- Jun 2006

- Location

- Poland

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Very interesting...

Perhaps they were mostly making items that didn't suffer too much from sulfurization of iron/steel due to stone coal reactions.

Or perhaps they've found some other solutions.Avatar by KwarkpuddingThe subtle tongue, the sophist guile, they fail when the broadswords sing;

Rush in and die, dogs—I was a man before I was a king.

Whoever makes shoddy beer, shall be thrown into manure - town law from Gdańsk, XIth century.

-

2014-08-01, 12:18 PM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Yeah that is what I thought too, I recently learned differently. They were making widespread use of coal in Flanders and northern Germany (starting in Aachen) as early as the 1220's. It spread to England, France and Italy and beyond indeed, into parts of what is now Poland (including Silesia, and I think some other areas but I'd have to check) largely due to the increasing cost of wood due to deforestation and the value of wood for other purposes. It became the main method of smelting iron and powering forges and bloomery forges, as well as the early blast furnaces. Some regions including parts of Poland seem to have never run out of trees so maybe that is why it didn't spread there.

It was also being used for many other purposes such as heating water for bath-houses and beer brewing, and was apparently so prevalent in many towns that several laws were passed limiting the use of certain (particularly nasty) types of coal as early as the 13th Century due to air pollution (smog, effectively). Apparently the easily accessible surface coal they were using then was even dirtier than most coal used today.

The production of cast-iron Cannon in Flanders were done with locally mined (from the surface) coal. My source for this is a book called The Medieval Machine, I'll post the page numbers tonight.

G

-

2014-08-01, 12:19 PM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Yeah, I really don't know. Maybe the sulfurization is more of a problem when they actually melt the iron (in the blast furnace) as opposed to just heating it up in the forge.

Apparently it was pretty nasty stuff though and unpopular, it was eventually banned for using in baking ovens in some places but they continued to use it for beer brewing in England for a long time.

G

-

2014-08-01, 12:28 PM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

This wiki mentions coal mining in England from the 13th century, it also says the use of coal declined there after the Black Death due to the return of forests. It also says the first blast furnace in England was established in 1496.

http://en.wikipedia.org/wiki/Economi...he_Middle_Ages

G

-

2014-08-01, 09:07 PM (ISO 8601)Ogre in the Playground

- Join Date

- Sep 2008

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Well, iron cannons usually had to be made thicker than bronze cannons, although the quality of the iron mattered (swedish iron had a good reputation). Nevertheless, I think what is meant by "more durable" has to do with how quickly the gun would wear out -- and not how resistant they were to blowing up. Iron had a bad reputation, and a marginal design could be problematic. By the middle of the 19th century the science was getting better and the "Rodman" style cannons showed a more scientific approach in both design and manufacture. Nevertheless, the famous cast iron Parrott cannons, were known for occasionally exploding, whereas the iron Ordnance rifles were hammer welded, and were known for reliability, but were very expensive.

-

2014-08-01, 09:17 PM (ISO 8601)Ogre in the Playground

- Join Date

- Sep 2008

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Returning to the issue of repairing steel swords -- I don't think it was a trivial matter. Biringuccio in his Pirotechnia (written sometime before 1540), describes a kind of solder that can be flowed into cracks in a sword to repair it. My suspicion is that it's a suboptimal way of repairing a sword (despite the author's claims), but if repairing a steel sword was simple I doubt it would have been suggested in the first place.

-

2014-08-01, 09:46 PM (ISO 8601)Bugbear in the Playground

- Join Date

- Jul 2013

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

So this isn't quite a a weapon or armor question, but I figure someone here might know. I am currently watching the Desolation of Smaug, and am wondering how Bard is moving his barge in the water. First I'll say that I know just about nothing about watercraft, so the little bit of terminology I'm going to throw out could be horribly wrong. It's basically what I could find with a little bit of wikipedia browsing.

So it looks like during the trip, he's holding on to the "tiller." And from what I understand, that attaches to the "rudder," which is used to steer a boat. In the movie, he puts his hand on the tiller, waggles it around, and can both steer and propel the boat forward. No oars, no unfurled sails, and it doesn't look like the water is moving them forward.

Can someone really do that? Was it a simplification because they didn't want to actually bother about sailing? Have I just misidentified the parts? Is there a completely different mechanism I just don't understand?

Thanks in advance. And I'm really not trying to be the guy who just points out everything wrong in a movie. I just don't know very much about boats/ships/etc., and I'm quite curious if a method like that actually exists.

-

2014-08-01, 10:10 PM (ISO 8601)Ogre in the Playground

- Join Date

- Oct 2009

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

The other problem with using iron, is that being ferrous, it's much more prone to accidental sparks.

I also agree with you about repairing iron swords, I don't think it was so easy. I'd be very reluctant to use a sword which had been fixed that way (or which had had a major crack in it and been fixed any way other than a complete reforging). The little dings you basically hone out, until there isn't enough of the sword left for it to be a sword any more, then the typically turn it into a knife or a dagger of some kind. It was the fate of many claymores to become dirks and later sgian dubh.

The stuff about the medieval use of coal for iron forging which I promised to provide a reference for earlier is in that book The Medieval Machine which I mentioned previously, on pages 81-84

G

-

2014-08-01, 10:30 PM (ISO 8601)Dwarf in the Playground

- Join Date

- May 2007

- Location

- Northern Ohio

- Gender

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Re: Got a Real-World Weapon or Armour Question? Mk. XV

Scroll down to the section on "Single-oar sculling" on the Wikipedia page for Sculling. That could be what you're seeing.

DrewID

-

2014-08-01, 10:45 PM (ISO 8601)Bugbear in the Playground

- Join Date

- Jul 2013

Reply With Quote

Reply With Quote

RSS Feeds:

RSS Feeds: